- Levin Winzinger

- 19.02.26

- 6 min

- Success factor sustainability, Bioeconomy

Your contact person

Dr Günter Hohmann

The hydrogen infrastructure is crucial for the successful introduction of hydrogen and its many applications on the market. Widespread availability of hydrogen is essential to meet the needs of all users. This requires either the construction of new hydrogen pipelines or the retrofitting of existing pipelines. In addition, an efficient storage structure must be created to stabilize the production of hydrogen. This article highlights the challenges and possible solutions, including support programs and chemical storage of hydrogen.

Each year, about 2% of the natural gas produced worldwide is lost due to leakage during production, transportation, or compression. When converting the infrastructure from natural gas to hydrogen, even greater losses due to leakage can be expected compared to natural gas: Firstly, because hydrogen molecules are smaller and can escape more quickly. Secondly, because of so-called hydrogen embrittlement, in which hydrogen penetrates atomic metal structures and causes microcracks.

Various development measures are required for a hydrogen-capable infrastructure:

The development of such measures can be supported by various funding programs such as the tax-based research allowance (steuerliche Forschungszulage) or KMU-innovativ.

|

|

||

|

Tax research allowance to promote hydrogen projects |

Hydrogen is a good energy store: relative to its weight, its energy content is much higher than that of other fossil fuels, for example. However, hydrogen occupies a lot of space at normal temperatures and is highly volatile. Its low energy density can be increased and maximized by compression or liquefaction, which is crucial. This is because liquid hydrogen storage has a much higher energy density than gaseous storage, making it much easier to transport H2. Current storage options for hydrogen are:

Therefore, new storage and transport methods are needed for the long-distance transport of hydrogen. The current possibilities are as described below.

Figure 1: Modern hydrogen storage system accompanied by a large solar power plant and wind turbine farm

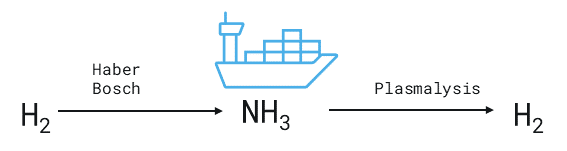

One way to simplify hydrogen storage and transport is to chemically convert hydrogen. One approach is to convert hydrogen with nitrogen to ammonia using the Haber-Bosch process. Ammonia is easier to store in large quantities because it is already liquid at medium pressures without cooling. Unlike hydrogen, ammonia can be transported with less effort and without active cooling.

Liquefied ammonia can be transported over long distances, for example by tankers. At the destination, the hydrogen must be recovered from ammonia, which can be done, for example, by plasmalysis or electrolysis (see Figure 2). The goal is to maximize the amount of energy transported and to minimize energy loss during transport and recovery.

Figure 2: Transport of ammonia by tankers

There is still potential for development in the chemical conversion and recovery of hydrogen. The production of ammonia by the energy-intensive Haber-Bosch process requires improvements to increase energy efficiency. Similarly, hydrogen recovery processes need to be further developed and optimized to achieve a positive energy balance.

Hydrogen supply requires more than just transportation and storage. Additional components are needed to link production and consumption to the hydrogen infrastructure. Processes must be regulated and supplies of other raw materials must be secured. These essential components that ensure the operation of hydrogen processes are referred to as "balance-of-plant." They include tasks such as pressure control, temperature control, provision of electrical power, feedstock supply and control systems.

The needs in the hydrogen economy are many and varied. If you have ideas for research and development in the field of hydrogen, we will be happy to assist you. For more information on hydrogen, visit www.eura-ag.com/en/industries/hydrogen-consulting.

Text: Georg Beckmann

Your contact person

Dr Günter Hohmann

EurA AG

T- 079619256-0Max-Eyth-Straße 2

73479 Ellwangen

info@eura-ag.com