- Mareike Deggelmann

- 26.01.26

- 3 min

- Funding advice, Agrifood, Bioeconomy

Your contact person

Dr Günter Hohmann

The hydrogen industry is on the upswing. However, to meet the market demand for environmentally friendly hydrogen, H2 must be produced from renewable raw materials and without emitting greenhouse gases. Find out what the technical options and specific subsidies are for this in this blog article.

Hydrogen is being traded as the clean energy storage of the future, but so far it has been produced primarily from fossil raw materials and with the release of CO2. In order to produce hydrogen in a climate-neutral way, production must be switched to sustainable raw materials and to greenhouse gas-free processes. To achieve this, green hydrogen production processes must be further developed and scaled up to the point where they can replace existing processes. This is where current R&D projects can come in and be advanced with funding. And this will be worthwhile: The industrial sector around hydrogen will undergo strong growth in the coming years. As part of this, scaling all hydrogen-related sectors - production, transport and storage, consumption, and control components (balance-of-plant components) - is critical. By investing at the right time, companies can gain a decisive market advantage.

How is hydrogen currently produced and what is the problem with it?

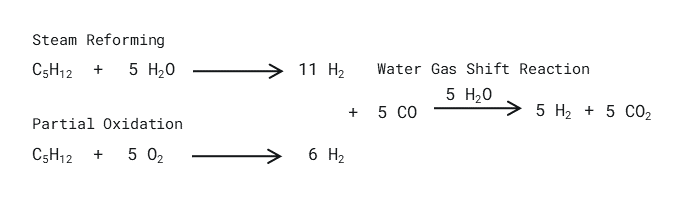

Until now, most of the hydrogen produced has been made from fossil raw materials and with the release of CO2. For the production of this, so called grey hydrogen, the following processes are used:These processes rely on fossil feedstocks and release approximately 16.1 kg CO2 eq/kg H2. Due to these high greenhouse gas emissions, decarbonization cannot be achieved based on gray hydrogen.

Figure 1: The different reactions for the production of hydrogen starting from pentane.

Which processes are used for the production of sustainable green hydrogen?

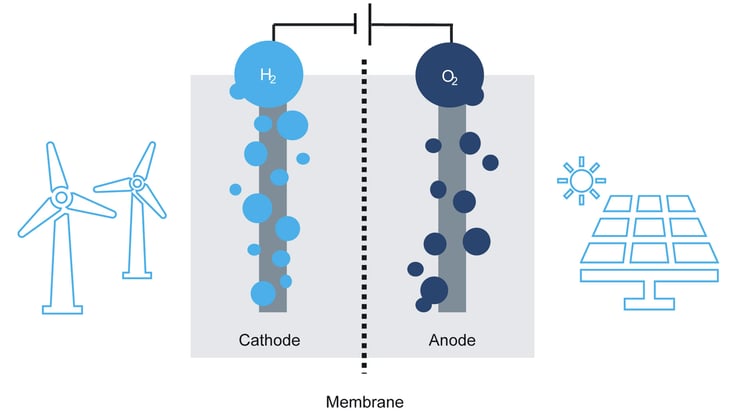

Electrolysis is considered to be the most important process for the production of hydrogen in the future. In an electrochemical process, water is split into hydrogen and oxygen. Provided the energy for electrolysis comes from renewable sources, no greenhouse gases are thus released and the hydrogen produced is accordingly climate-neutral. Even using electricity from fossil sources, the greenhouse gas release of approx. 1.5 kg CO2 eq/kg H2 is significantly lower than for gray hydrogen.

What alternative processes can be used to produce green hydrogen?

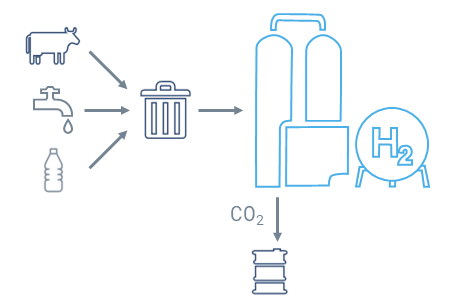

Apart from hydrogen produced by electrolysis, there are also other methods to produce sustainable hydrogen. One possibility would be to process waste products into hydrogen. Biomass, such as sewage sludge from water processing or liquid manure from animal husbandry, is particularly suitable for this. Due to their high content of bound hydrogen atoms, plastic waste is also attractive for recycling.

Figure 3: Possible waste for the production of green hydrogen.

Biomass is processed in two steps: It becomes fertilizer and residues are fed to energy production, mostly via biogas production. By converting the biomass to hydrogen via gas reforming or partial oxidation, hydrogen can be produced with the generation of CO2 as a co-product. In the same way, non-recyclable plastic or wood waste, for example, can be processed. In the energy recovery of all these materials, CO2 would inevitably be produced. Carbon capturing methods or the material recycling of the carbon-containing intermediate products can completely eliminate the release of CO2. The HyWaste network, managed by EurA AG's hydrogen experts and funded by the Central Innovation Program for SMEs (ZIM), deals with various topics related to the generation of hydrogen from problematic materials. If you are active or interested in this field, please do not hesitate to contact us.

In addition to processes for the specific production of hydrogen, hydrogen can also be produced as a co-product or by-product in processes. One of the biggest examples is chlor-alkali electrolysis, which is actually used for the production of chlorine (approx. 80 million tons per year), but releases high amounts of hydrogen (approx. 2 million tons per year). Hydrogen is also produced as a co-product in petrochemical processes, such as the production of ethylene or gasoline production. In these large-scale processes, hydrogen is already specifically extracted and further utilized. However, there are many smaller processes, especially in the field of electrolysis processes, in which hydrogen produced as a by-product is released or burned via a flare instead of being isolated.

|

Funding and support for hydrogen projects

You will receive further information on this blog as soon as the full funding guideline is available. |

You want to advance your projects in the field of hydrogen and are looking for suitable funding or want to learn more about the opportunities and advantages of hydrogen? EurA AG's Aachen and Herten sites have years of experience in successfully applying for funding and providing technical advice on hydrogen. Contact us, we will advise you on the selection of the right funding program and will be happy to support you in the application process.

Text: Georg Beckmann

Your contact person

Dr Günter Hohmann

EurA AG

T- 079619256-0Max-Eyth-Straße 2

73479 Ellwangen

info@eura-ag.com