- Mareike Deggelmann

- 26.01.26

- 3 min

- Funding advice, Agrifood, Bioeconomy

Your contact person

Dr Greta Maroun

Since this spring, it has been clear what has been forecast for a long time: The PFAS group of substances is to be banned in its entirety according to a proposal by five EU states, including Germany. A corresponding process has already been initiated at EU level.1

We explain what PFAS are, why they are about to be prohibited now, when a ban can be expected and what impact this may have on the German industry.

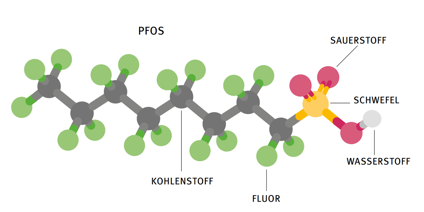

PFAS stands for per- and polyfluorinated alkyl substances; a group of substances characterised by their long chains of carbon and fluorine atoms (Figure 1). The PFAS group now includes more than 4,700 synthetic chemicals that have been used in industrial processes and products on a large scale since the 1940s. The diversity in appearance and properties of the individual substances, which e.g. appear in solid, liquid or gaseous form, is as large as their number.2,3

PFAS are sought-after in industry primarily because of their high resistance to extreme temperatures and aggressive chemicals, their highly water- and oil-repellent properties and their electrical insulating properties. However, their high stability also means that they are virtually non-degradable, neither in the environment nor in living organisms. This is why they are also called "eternal chemicals" in German (“Ewigkeitschemikalie”).3

Very well-known examples of PFAS are TeflonTM and Gore-TexTM.3 However, substances such as PVDF, PFA, FEP, PCTFE and ECTFE, which are used in chemically and/or thermally demanding applications such as for lining pipes or exterior components or in solar cells, also belong to the group of substances.4

Figure 1. Example of a PFAS: perfluorooctane sulfonic acid (PFOS).The fluorine atoms attached to the long carbon chains are responsible for both the industrially interesting properties and the health and environmental risks of the group of substances. Source: Umweltbundesamt.2

The push to ban PFAS as an entire group is unique in its extent, because so far there are only relatively few well-studied PFAS. However, most of these are known as moderately to highly toxic, especially for the development of children. Individual bans are thus already implemented, such as of PFOA (perfluorooctanoic acid, applications include non-sticking coatings, photos, medical products) and PFOS (perfluorooctane sulfonic acid, applications include carpets, textiles, paper).4 The GenX manufacturing process - which was developed in response to the PFOA ban and appeared to be an alternative and less harmful manufacturing process - turned out to be "of particular concern" in retrospect.5

Because they do not degrade, PFAS accumulate in human tissues and the environment over time. They can lead to health problems such as liver damage, thyroid disease, obesity, fertility problems and cancer.6 It is also estimated that more than 12,000 people die each year in the EU in connection with excessive PFAS exposure.7 According to the German Federal Environment Agency (Umweltbundesamt), PFAS can be detected in the blood of almost all people, including in Germany.2

The economic costs to society of exposure to PFAS have been conservatively estimated by the Nordic Council of Ministers to lie between 52 and 84 billion euros per year in Europe.8 Similar figures were recently calculated by a team from New York University for the USA, with estimated costs ranging from five and a half to more than 60 billion euros for therapies, medicines and lost work.7 Further costs arise from the pollution of ecosystems and the resulting necessary clean-up of polluted soil and water. There are no reliable figures on this issue yet.

The areas of application for PFAS are as diverse as the substance group itself. Teflon, for example, is used in coated pans as well as in sealing components of chemical plants.

Other examples of PFAS use include everyday items such as pans, baking tins, cable sheathing, seals, medical hoses, impregnation and textiles, but also high-tech water filters, lubricants and adhesives, propellants and refrigerants, aerospace components, fuel and electrolysis cells and binders in electrodes of lithium ion batteries. The latter, in particular, are highly relevant in the context of the energy transition and should be planned into developments at an early stage. For example, PFASs are critical components in proton-conducting membranes and in the sealing of fuel cell stacks for which there is currently no commercial alternative.9

In addition, PFAS are used as auxiliaries in many manufacturing processes, e.g. in the chemical and semiconductor industries. Often this is not apparent in the final product and manufacturers need to look closely at their supply chain to avoid future production losses. Components for electronic devices such as mobile phones or computers, for example, are manufactured with the help of PFAS. In the surface treatment of metals and plastics, PFAS are used as wetting agents to suppress chromium (VI) vapours in chrome-plating processes and in plastic pickling.7,10

The European Chemicals Agency (ECHA) wants to ban the production as well as the use and import of PFAS. What exceptions there will ultimately be is still unclear. Nevertheless, the question is not whether the ban will come, but in what form. Exemptions are planned to be time-restricted.11

Transition periods of between eighteen months and thirteen and a half years are currently being discussed, depending on the sector and application. Thus, the first restrictions can probably be expected in 2025. The basic rule is: the more essential the application, the longer one can expect a grace period. Medicinal products could possibly pass as an open-ended exception.3

Nevertheless, a switch to PFAS-free production should not be postponed for too long. Conversions of production lines and products sometimes require many years of development. Replacement technologies still have to be developed to market maturity. This can lead to a shortage of PFAS-free substitute products.3

The European Chemicals Agency (ECHA) wants to ban the production as well as the use and import of PFAS. What exceptions there will ultimately be is still unclear. Nevertheless, the question is not whether the ban will come, but in what form. Exemptions are planned to be time-restricted.11

Transition periods of between eighteen months and thirteen and a half years are currently being discussed, depending on the sector and application. Thus, the first restrictions can probably be expected in 2025. The basic rule is: the more essential the application, the longer one can expect a grace period. Medicinal products could possibly pass as an open-ended exception.3

Nevertheless, a switch to PFAS-free production should not be postponed for too long. Conversions of production lines and products sometimes require many years of development. Replacement technologies still have to be developed to market maturity. This can lead to a shortage of PFAS-free substitute products.3

|

EurA AG is happy to support projects that aim to develop PFAS-free alternatives. As a strong partner in conceptualisation, partner identification and subsidies, we can provide our services and networks to facilitate the conversion of your processes, e.g. by applying for suitable funding. Life cycle analyses can provide insight into the real share of PFAS in process chains and at the same time serve as proof of PFAS-free production. Our networks in the fields of surface technology, hydrogen, aerospace and medicine can help you find further ideas and necessary cooperation partners.

|

||

Text: Dr. Greta Maroun

[1]Science Media Center Germany. Mögliches Verbot der PFAS. 07. Februar 2023. https://www.sciencemediacenter.de/alle-angebote/rapid-reaction/details/news/moegliches-verbot-der-pfas/ (accessed 2023-05-17).

[2]Poetschke, F. Schwerpunkt 1-2020: PFAS. Gekommen, um zu bleiben.; Umweltbundesamt, 2020.

[3]Schneider, M. Auswirkungen eines PFAS-Verbots auf die Chemie-Lieferkette. CHEMIE TECHNIK. 28. Februar 2023. https://www.chemietechnik.de/markt/pfas-verbot-gefaehrdet-die-versorgungssicherheit-intransparenter-lieferketten-577.html (accessed 2023-05-17).

[4]Bock, S. PFAS, die Einschränkungen könnten weiter gehen. bock machining gmbh. 1. März 2022. https://www.bock-machining.de/pfas-die-einschraenkungen-koennten-weiter-gehen/ (accessed 2023-05-17).

[5]Schön, P. EU-Gericht: PFOA-Ersatz ist «besonders besorgniserregend». infosperber. 4. Mai 2022. https://www.infosperber.ch/wirtschaft/konzerne/eu-gericht-pfoa-ersatz-ist-besonders-besorgniserregend/ (accessed 2023-05-17).

[6]Europäische Umweltagentur. Was sind PFAS und inwiefern sind sie für meine Gesundheit gefährlich? https://www.eea.europa.eu/de/help/haeufig-gestellte-fragen-faq/was-sind-pfas-und-inwiefern (accessed 2023-05-17).

[7]Drepper, D.; Hoferichter, A. Nützlich, giftig, unverwüstlich. Süddeutsche.de. online. 23. Februar 2023. https://www.sueddeutsche.de/projekte/artikel/wissen/pfas-chemikalien-fragen-und-antworten-lebensmittel-schaedlich-e250554/ (accessed 2023-05-17).

[8]Goldenman, G.; Fernandes, M.; Holland, M.; Tugran, T.; Nordin, A.; Schoumacher, C.; McNeill, A. The Cost of Inaction : A Socioeconomic Analysis of Environmental and Health Impacts Linked to Exposure to PFAS; Nordisk Ministerråd, 2019.

[9]Leitstelle Wasserstoff. Stellungnahme - Auswirkungen Des Verbots Der Per- Und Polyfluorierten Chemikalien (PFAS); Nationaler Wasserstoffrat, 2023.

[10]Stoll, J. PFC in der Oberflächenbehandlung von Metallen und Kunststoffen. Umweltbundesamt. Umweltbundesamt. 24. Februar 2020. https://www.umweltbundesamt.de/pfc-in-der-oberflaechenbehandlung-von-metallen (accessed 2023-05-22).

[11]Bähr, M. Nicht ob, sondern wann: das PFAS-Verbot kommt | reuschlaw News. reuschlaw. 13. März 2023. https://www.reuschlaw.de/news/nicht-ob-sondern-wann-das-pfas-verbot-kommt/ (accessed 2023-05-17).

Your contact person

Dr Greta Maroun

EurA AG

T- 079619256-0Max-Eyth-Straße 2

73479 Ellwangen

info@eura-ag.com